User Tools

Sidebar

Table of Contents

Appendix 4: Switch

In geotechnics, one is often constrained to deactivate progressively some finite elements, so that a hollow proceeding is simulated and to activate other finite elements, modeling the progressive appearance of a support or a stratum construction.

In metal forming processes such as continuous casting or additive manufacturing, thermal boundaries (CONRA element) or material modeled by solid elements can appear.

The present appendix proposes a solution for these types of problems.

The switch process is activated by the variable ISWI=1 on the 3rd line of the execution data (ex.dat). It essentially concerns the sub-program ELEMB. The concerned elements are already present in the lag files but the switch file determines their activation. If they are inactive, the stresses, internal variables and the stiffness matrix are potentially put to zero (NSAVES variable defines it). Otherwise they are computed and saved as usually.

The various stages: hollow, building wall tunnel, cooling by water spray, new metal deposit etc must be distinguished. They are called phases hereafter.

The elements which are active during the whole computation do not have to be specified.

Data to be given in the file .SWI

| First line (6I5) | |

|---|---|

| NGR(I5) | Number of activation or deactivation phases (maximum value is currently 10000, changed by G. Gilles on May 2015. It’s possible to change this value!) |

| IFORM (I5) | = 0 the elements to be activated are written in the format 14I5 ≠ 0 the elements to be activated are written in the format 9I10. This is useful when the number of nodes exceeds 10 000 |

| iOFF_elem(I5) | Maximum number of deactivated elements at any given IGR |

| iON_elem(I5) | Maximum number of activated elements at any given IGR |

| iTFORM(I5) | When this number is equal to 1, the format for the definition of activation and deactivation moments is G15.0 (instead of G10.0) |

| NFRMT(I5) | Use the new format, which allow transform intervals, see below example 3, tested only for OFF groups |

Group of 1+NPICS(IGR) lines repeated NGR times

| Line 1 - (2I5) | |

|---|---|

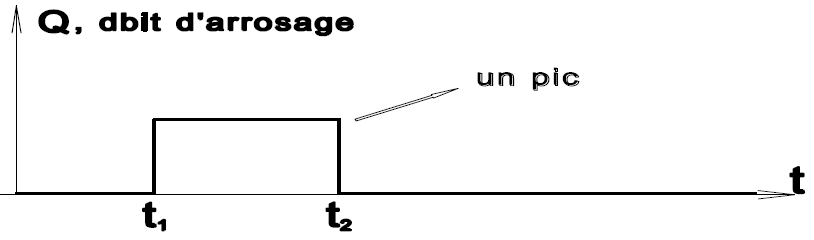

| NPICS(IGR) | Number of peaks (see figure 1) for each phase ≤ 20 (maximal value in the code) |

| NSAVES(IGR) | Normally, when an item is deactivated, stresses and state variables of this element are canceled. Sometimes, however, it is interesting to keep track of either the stresses or the state variables, or both. The NSAVES variable allows to manage this problem, according to its value the following data is stored: = 0 stresses and state variables are set to 0 = 1 computed stresses are stored and computed state variables are set to zero = 2 computed state variables are stored and computed stresses are set to zero = 3 computed stresses and state variables are stored |

| Line 2 to NPICS(IGR) - (2G10.0) or (2G15.0) if iTFORM=1 | |

| PICAR (IPIC,1,IGR) IPIC=1,NPICS | Activation moment - it can be equal to 0, in this case, the elements are active since the beginning of the analysis |

| PICAR (IPIC,2,IGR) IPIC=1,NPICS | Deactivation moment - it can be greater than the duration of the analysis, in this case, when they are active, the elements stay present until the end of the analysis |

| TDECAL(IGR) | = 0 Nothing ≠ 0 Intervalle de creusement (???) |

Second group of lines repeated NGR times

This group of lines details the activated and deactivated elements in each IGR phase.

| Line 1 (A5, I5) | |

|---|---|

| Title1 | “GR ” in the first 5 columns (GR followed by 3 blank spaces) |

| IGR | Phase number |

| Elements to be activated (A2/(14I5) or (9I10) is IFORM ≠ 0) | |

| Title2 | “ON” |

| LISTE(I) | List of elements to be activated Repeated as many times as necessary If a “-” sign is placed before the element number, all elements between the previous one and the 'negative' element will be activated. The list ends when a 0 value is encountered |

| Elements to be deactivated (A3/(14I5) or (9I10) is IFORM ≠ 0) | |

| Title3 | “OFF” |

| LISTE(I) | List of elements to be activated Repeated as many times as necessary If a “-” sign is placed before the element number, all elements between the previous one and the 'negative' element will be deactivated. The list ends when a 0 value is encountered |

Examples

Example 1: Cooling

The simulation of some coolings requires by turns the presence of radiation elements (natural cooling) or convection elements (spray).

Fig. 1

Fig. 1

→ at time t1 the elements CONRA (flow) are active

The elements CONRA (natural convection) and ECHRA (natural radiation) are deactivated.

→ at time t2 the activated elements are inverted.

Example 2: Laser cladding

In laser cladding, the heat flux of the laser is applied element after element using CONRA elements and new solid elements are added.

Distribution of the flux defined by .LOA on solid elements that must be activated.

CONRA element must also be activated on these elements.

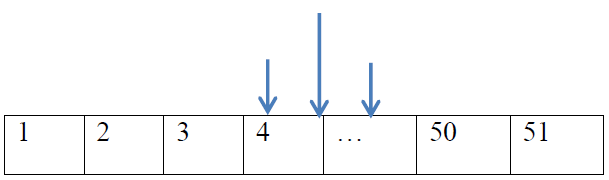

52 nodes at surface → NGR: 50 (It can be considered as the number of steps)

51 solid elements (elements 1, 2, 3 are active when the laser flow is on the top of element 1,2, then the laser moves on the top of element 2 and 3 and element 4 is activated).

The first line of the .SWI file will be:

50 0 50 50 0

The final time is 6s; the time required for one phase is 6/NGR=0.12 s.

We want to store the stresses and state variables.

The .SWI file will have the following group of lines:

50

1 3

0.0 0.12

1 3

0.12 0.24

...

1 3

5.88 6.0

Example 3: Laser cladding with NFRMT = 1

The idea is to simplify the use of switch by making the creation of the .swi file easier

Every element that belongs to a group will be replace in the group/groups to which it corresponds.

For example, elements of GR 2 will be place in the reoganized groups GR 1, GR 2, GR 3 and GR 4.